Heliostat

Technology Developer Survey Results

Responses were collected from 14 CSP technology developers on industry trends regarding heliostats and solar fields to inform the development of standards and guidelines.

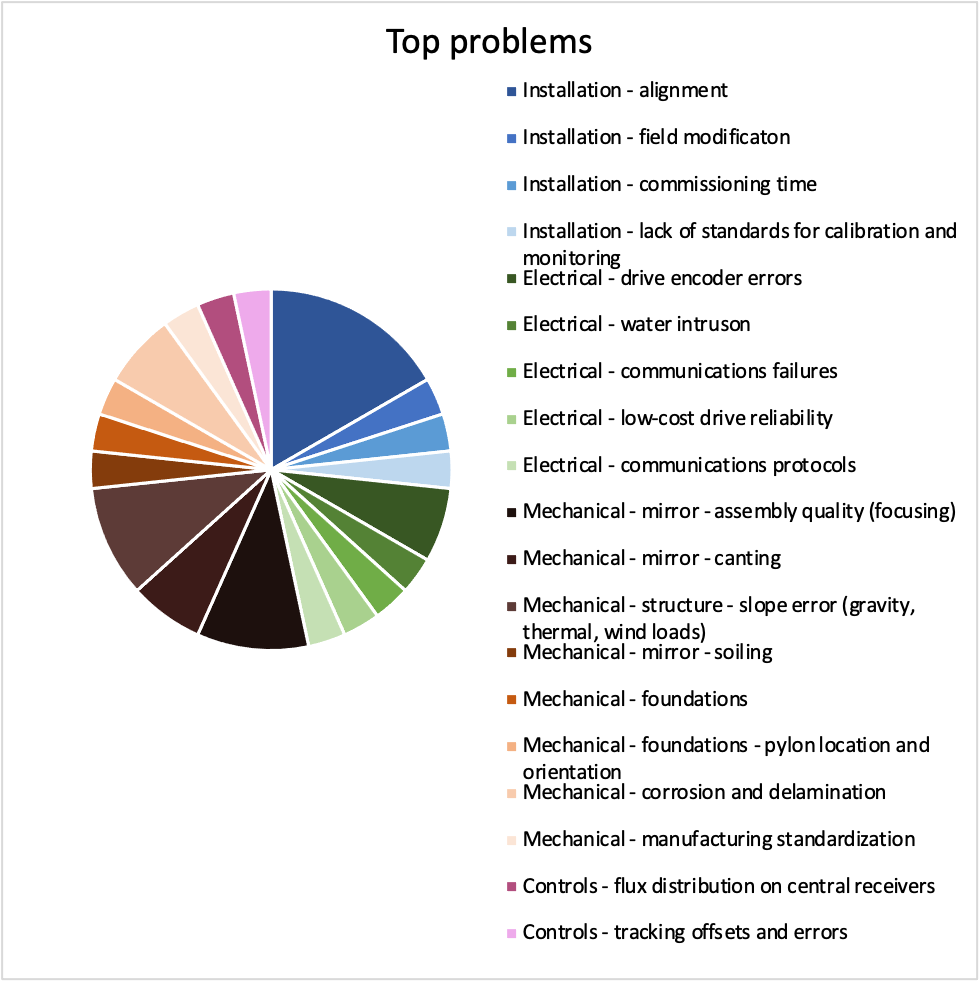

Alignment during installation is the most frequent top problem, and mirror canting and focusing on mechanical aspects are the second frequent top problems.

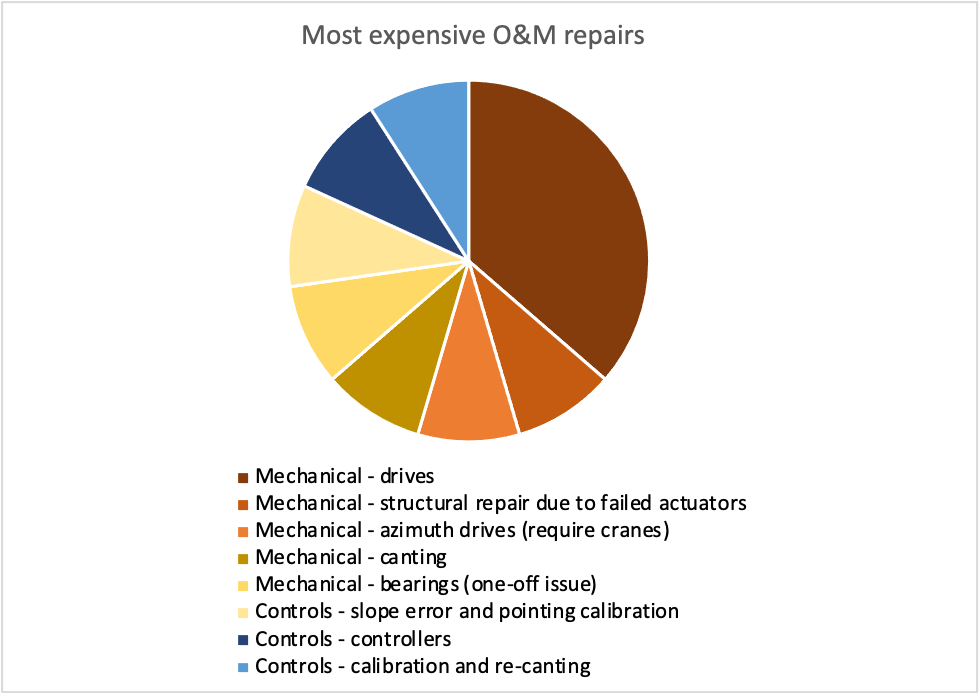

Drives repairs cost is the most expensive O&M repairs from the survey results.

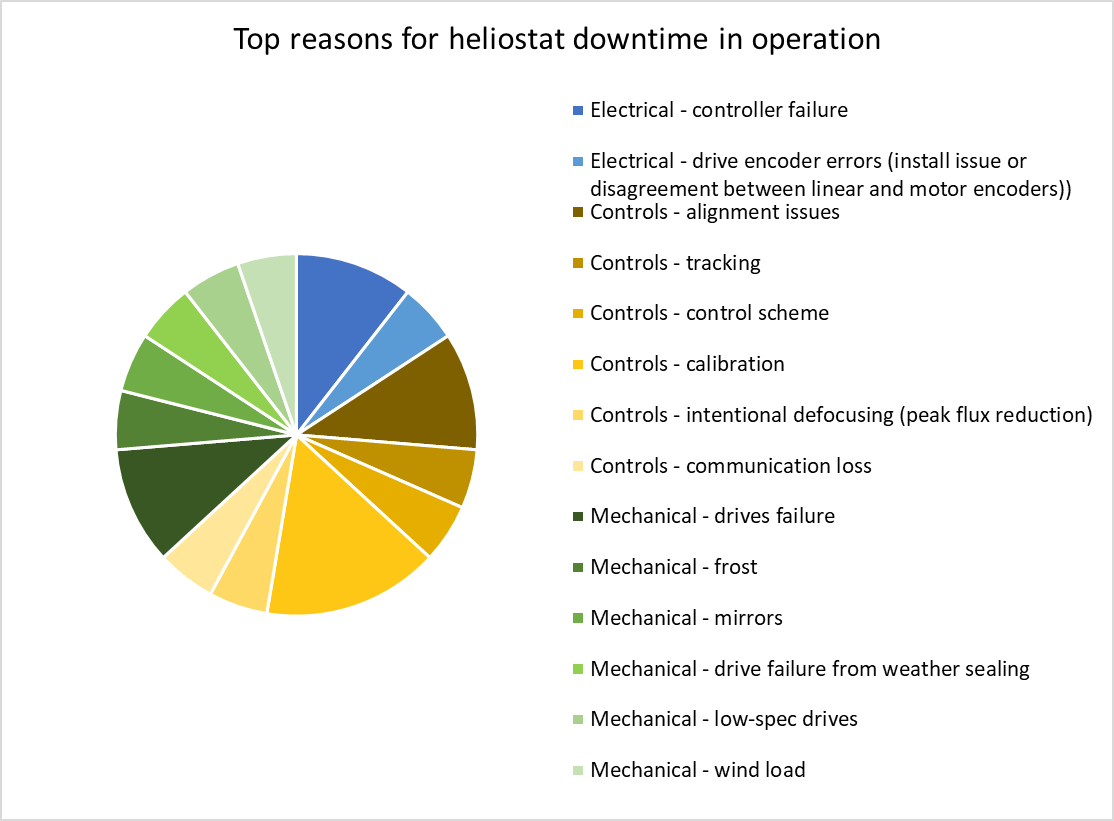

Calibration of control system

is the most common reason for heliostat downtime in operation.

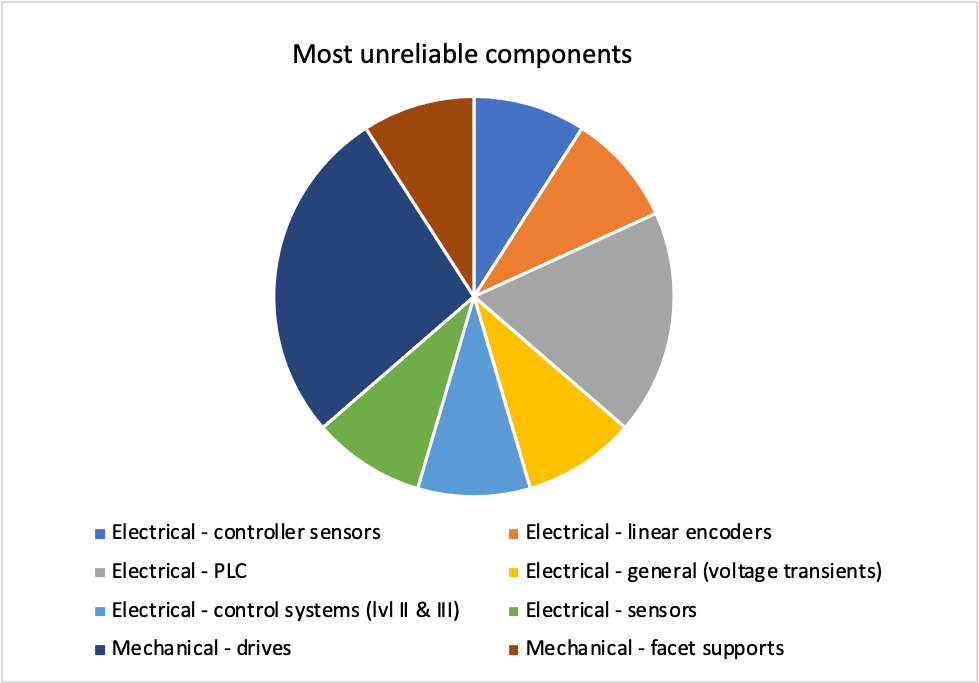

Drives are the most unreliable components, and PLC in electrical aspects are also unreliable sometimes.

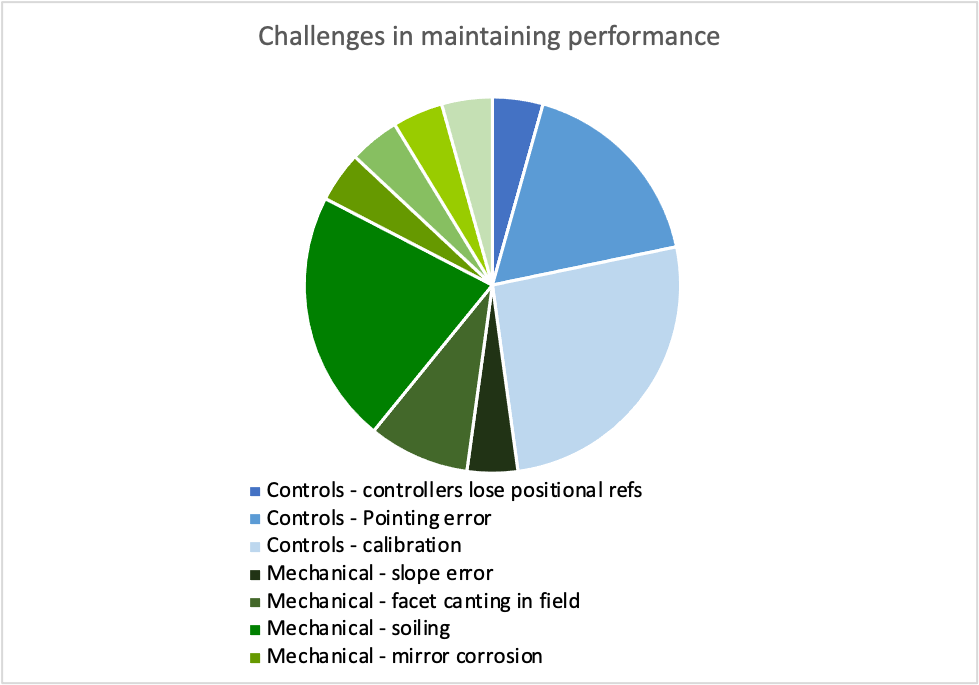

Pointing error and calibration in control process, and the soiling issue are the common challenges in maintaining performance. Calibration is the most common challenge.

Other results showed that 87.5% of the answers indicated yes

for having significant soiling issues. 85.6% of answers showed that there is a need for codes and standards,

and mainly require codes and standards for commissioning, incl. comms &

performance. For the resiliency & security problems, 58.3% of results

showed that resiliency and security is a concern, the rest of the answers

thought it is not a concern. The concerns are focused on following problems:

parts availability, modern tracking accuracy

is worse than the established accuracy in DOE experiments 40 years ago, excessive local wind load regulations, characterization, communications

system security, vegetation management, ID of lost heliostats, and lifecycle

testing of low-cost drives.

It was also suggested that

research should focus on mirror cost and quality, all component

reliability(incl.) weathering, and focused mirrors, heliostat automation,

calibration and monitoring.