Techno-economic Analysis

Lead: Alex Zolan, NREL alexander.zolan@nrel.gov

Co-Lead: Ken Armijo, SNL kmarmijo@sandia.gov

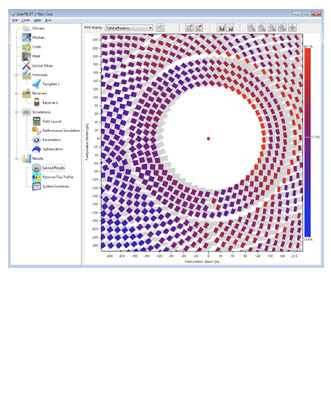

The Techno-Economic Analysis (TEA) topic uses models and analysis to quantitatively assess the benefits of heliostat design, manufacturing, and operation concepts for HelioCon. One of the main objectives of the TEA topic is to relate the cost and performance of heliostats and heliostat components to the overall system performance. To do this, we developed three baseline cases to use for technoeconomic analysis in the consortium. We limit the scope of our study to the heliostat field, receiver, and tower performance based on the thermal energy collected by the HTF compared to its installed and operating costs, using the levelized cost of heat (LCOH) as the key metric in our analysis. The three baseline cases we developed are: (i) a large, commercial-scale electricity plant with a 100-MWe power cycle; (ii) a smaller, modular electricity plant with a 20-MWe power cycle and a 100-MWt receiver; and, (iii) a small, modular plant used for industrial process heat (IPH) with a 30-MWt receiver. We performed a parametric study on each case to determine the impact of key parameters on LCOH using SAM and SolarPILOT. Results show that LCOH is most sensitive to optical error and installation costs followed by the heliostat reflectance and O&M costs. The baseline LCOH ranges from 1.8 to 2.8 cents/kWh of heat for the three cases and the parametric analyses consistently span about 0.5 cents/kWh of heat, regardless of the size of the plant.

Like other topics, TEA performed a gap analysis. Most of the gaps are related to developing models or data. The need for a linkage between model inputs and actual components is considered the most important gap. Specifically, a concerted effort is needed to better understand field O&M and the trade-offs between O&M costs and system performance. We also require a better model of high-temperature IPH applications. The TEA topic assists other topics in their gap ranking by estimating the potential impact of their gaps on LCOH if they are solved (or remain unaddressed). This ranking is performed by first interpreting the impact of addressing the gap on various cost or performance measures for a given CSP plant, and implementing those changes in an instance of SAM. While the impacts are rough estimates, this TEA-informed ranking can still be useful as a means to estimate which gaps have the highest impact on the projected cost and productivity of future plant installations.