Featured Project - Archive

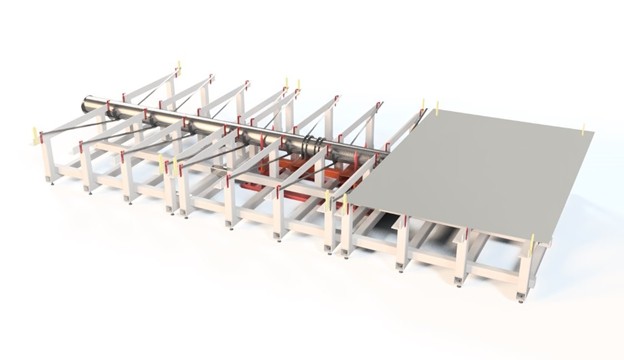

CAD model of mirror array workstation prototype with 1 facet placed. Sixteen vertically adjustable control points (highlighted in red) per facet allow 2-D focusing of mirror array.

Featured Project

Description:

This project by Solar Dynamics LLC develops an advanced on-site assembly line for its existing heliostat. The assembly line incorporates a new mirror array workstation that adds 2-D focusing to the mirror array. The steps required to deliver a complete heliostat field are also detailed from heliostat installation, commissioning, and O&M culminating in a comprehensive cost model capturing the heliostat’s full lifecycle cost.

Project Lead:

Kyle Kattke (Solar Dynamics)

Team: Nathan Stegall (Solar Dynamics), Patrick Marcotte (Solar Dynamics), Rick Sommers (Solar Dynamics)

Objectives:

- Re-design mirror array for integration with workstation that adds 2-D focusing

- Design on-site assembly line with automation being added where practical

- Detail the cost and schedule to perform all in-field work from heliostat install to lifetime O&M

Approach:

- Finite Element Analysis (FEA) used to optimize mirror array balancing cost and optical performance

- Mirror array workstation designed to impart 2-D paraboloid shape during assembly process

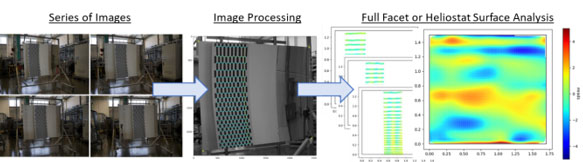

- Mirror array will be built with workstation prototype and Sandia’s SOFAST will be used to measure slope error of the mirror array. SOFAST measurements are used to tune workstation.

- Work with 3rd party automated assembly vendor to develop on-site assembly line

Status:

- Prototype mirror array components have been ordered, scheduled to begin prototype construction in August 2024

- Sandia is performing tests to confirm SOFAST screen details including the ability to perform measurements in ambient lighting conditions and the use of a low-cost stretched screen.

- Solar Dynamics has developed a conceptual on-site assembly line, and this will be refined by 3rd party automated assembly vendor (contract placed in July 2024).

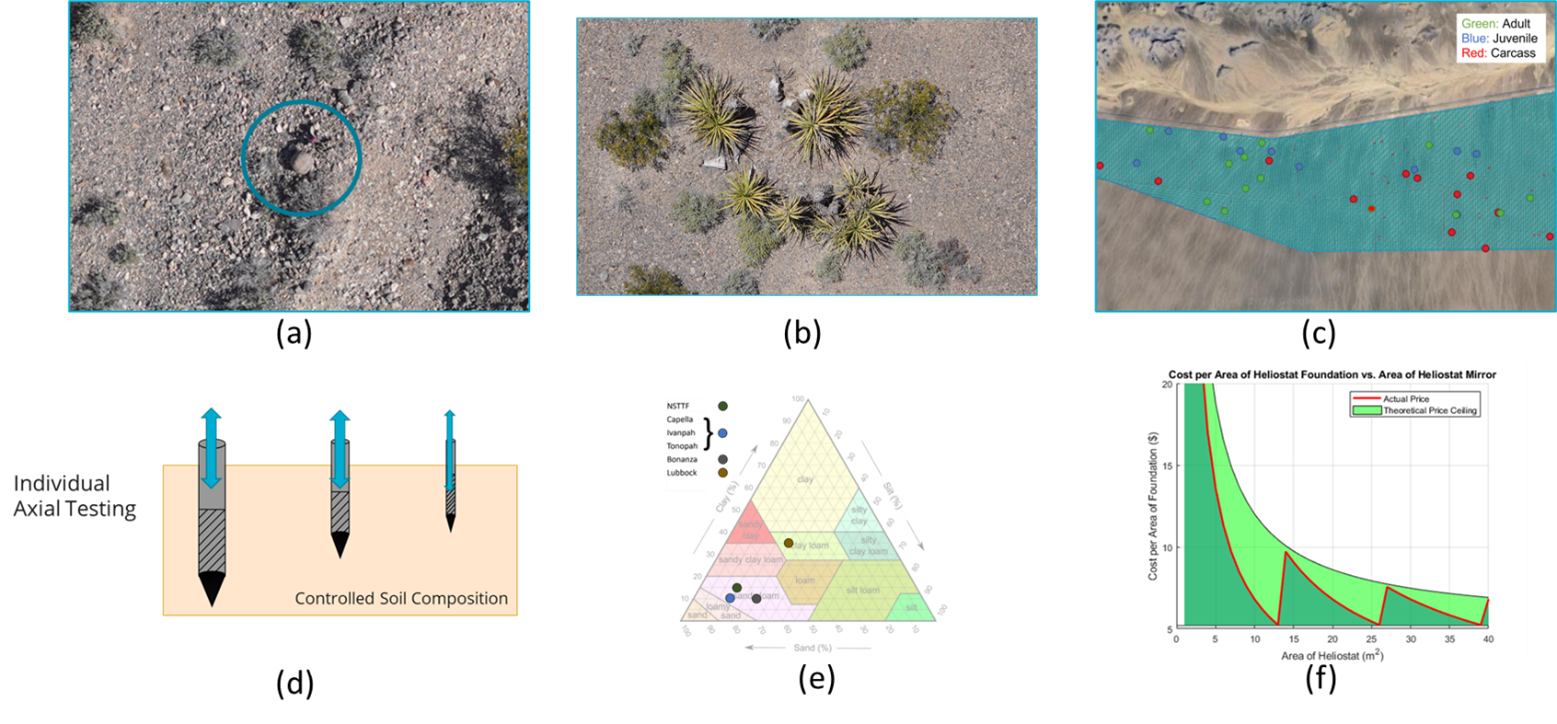

(a) UAV Tortoise Identification. (b) Full Size UAV Image. (c) UAV Flyover Preliminary Results. (d) Controlled ground screw performance test diagram example. (e) Soil Texture Pyramid for Relevant Sites. (f) Initial Foundation Cost Model Results.

Featured Project

Description:

Completion of an on-ground survey of the Bonanza Solar site by the team’s biologist, in addition to a complete UAV flyover study has been completed. A comparative report between the two methods and an overall characterization of the results, with a focus on the desert tortoise, is in progress. During these evaluations it was noted that the area has experienced drought conditions over the past few years which was speculated to be a contributing factor to a qualitatively higher than usual number of tortoise carcasses discovered by the drone flyover. Efforts have been made to expand a network of partnership with the BLM, FWS, USGS, academic research institutions, and private developers to further develop a large scale, long term, ecological study. Initial data acquired from a previous NREL project was analyzed to determine if temperatures inside and outside a deployment of parabolic troughs would be different. Additional data collection opportunities are being explored to further characterize ground conditions inside and outside a solar deployment.

In conjunction with the ecological cost assessment of heliostat, or PV, deployments on desert habitats, a financial cost assessment of deployment methods is focusing on technologies currently used and evaluated for PV. Specifically focusing on ground screws as a cost-effective foundation support, having drastically reduced environmental impact compared to blade and grade methods, the Sandia team is focused on creating references for ground screw style deployments to effectively support heliostats in a variety of soil compositions. These references are intended to reduce the overall deployment cost, for small heliostats (1 square meter area), by guiding the selection of adequate, but not oversized, ground screw style foundations in different CSP relevant areas. Preliminary cost modeling of ground screws as a foundation style, based on limited ground screw performance data, suggest small heliostats can most benefit from reduced foundation costs. A factorial experimental design has been identified to as the path toward statistically relevant results for this testing.

Project Lead:

Jeremy Sment (Sandia) / Aaron Spieles (Sandia)

Team: Pete David (Sundance Consultants), Matthew Bandy (Resi Solutions), Kristina Ji (Sandia), Brain Fournet (Sandia)

Objectives:

- The goal of the Sandia team is to deliver an initial ecological evaluation based on current results and leverage those findings to scope and propose a full-scale B.A.C.I ecological study with identified partners.

- The goal of the Sandia team is to deliver a ground screw performance model that better informs a location specific costing for small (facet area) heliostat deployments.

Approach:

- Evaluation and reporting on the current state of one partner site, Bonanza Solar to prepare scope for a full-scale B.A.C.I ecological study.

- Data acquisition of ground conditions in current deployments.

- CSP relevant soil composition data for controlled above ground testing for ground screws and limited in-ground testing at the NSTTF as permitting allows.

Status:

- On-ground (traditional) and UAV flyover surveys focused on the desert tortoise are complete.

-Full-scale B.A.C.I scope will be informed by the results from completed survey reports and comparison of methods. - Design of experiment and procedure is in progress. Procurement of necessary testing equipment is in progress.

-Cost model will be revisited after the ground screw performance testing is completed at the NSTTF. - • Sensor selection and sharing with NREL team for ground condition data acquisition is in progress.

Featured Project

Description:

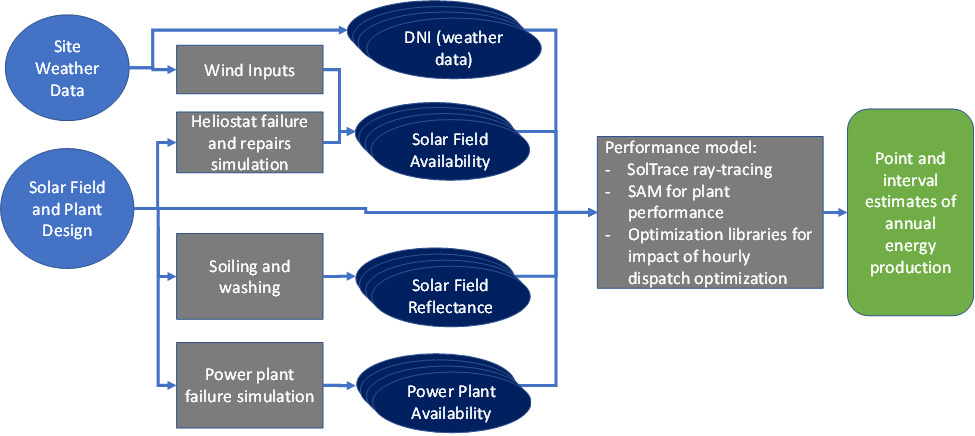

The objective of this subtask is to develop a high-fidelity, heliostat-based system performance prediction

model. Our approach uses Monte Carlo simulation to obtain point and interval estimates of plant

production and will characterize, then incorporate, several sources of uncertainty to obtain point,

interval, and percentile estimates of performance prediction

Project Lead:

Alex Zolan, NREL

Team: Evan Westphal (NREL) – less than 25%; Jeremy Sment (SNL) – less than 25%

Objectives:

- Assess the technoeconomic feasibility of developing CST tower systems for high-temperature industrial heat applications.

- Determine the impact of project size, operating temperature, and heliostat design on the levelized cost of heat and its ability to meet IPH demand.

Approach:

- Develop a simulation model that leverages existing performance characterization tools (i.e., SolarPILOT, SAM, SolTrace) and incorporates uncertainty in key inputs, including solar field availability, solar resource, optical performance, soiling, and modeling and measurement error.

- Generate case study comparing historical production to simulated performance model to compare empirical vs. simulated distribution of solar field performance.

- Package the software in a format that is accessible to the research and industry communities.

Status:

- Backcasting of historical Ivanpah plant production for a single year – completed last year

- Characterization of >= 3 sources of variation: completed this year

- Software package release: in progress; a repository on GitHub houses the code and will be released to the public next fiscal year.

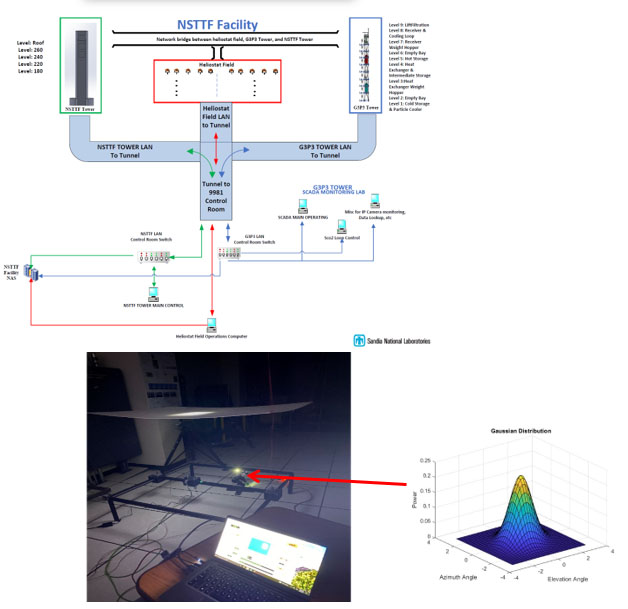

Sandia NSTTF Solar Tower with on-sun beam and BCS metrology image, used for feedback controls.

Sandia NSTTF Closed Loop Controls System Architecture.

Laboratory Closed Loop Controls Test bed for controls screening with a smaller target.

Featured Project

Description:

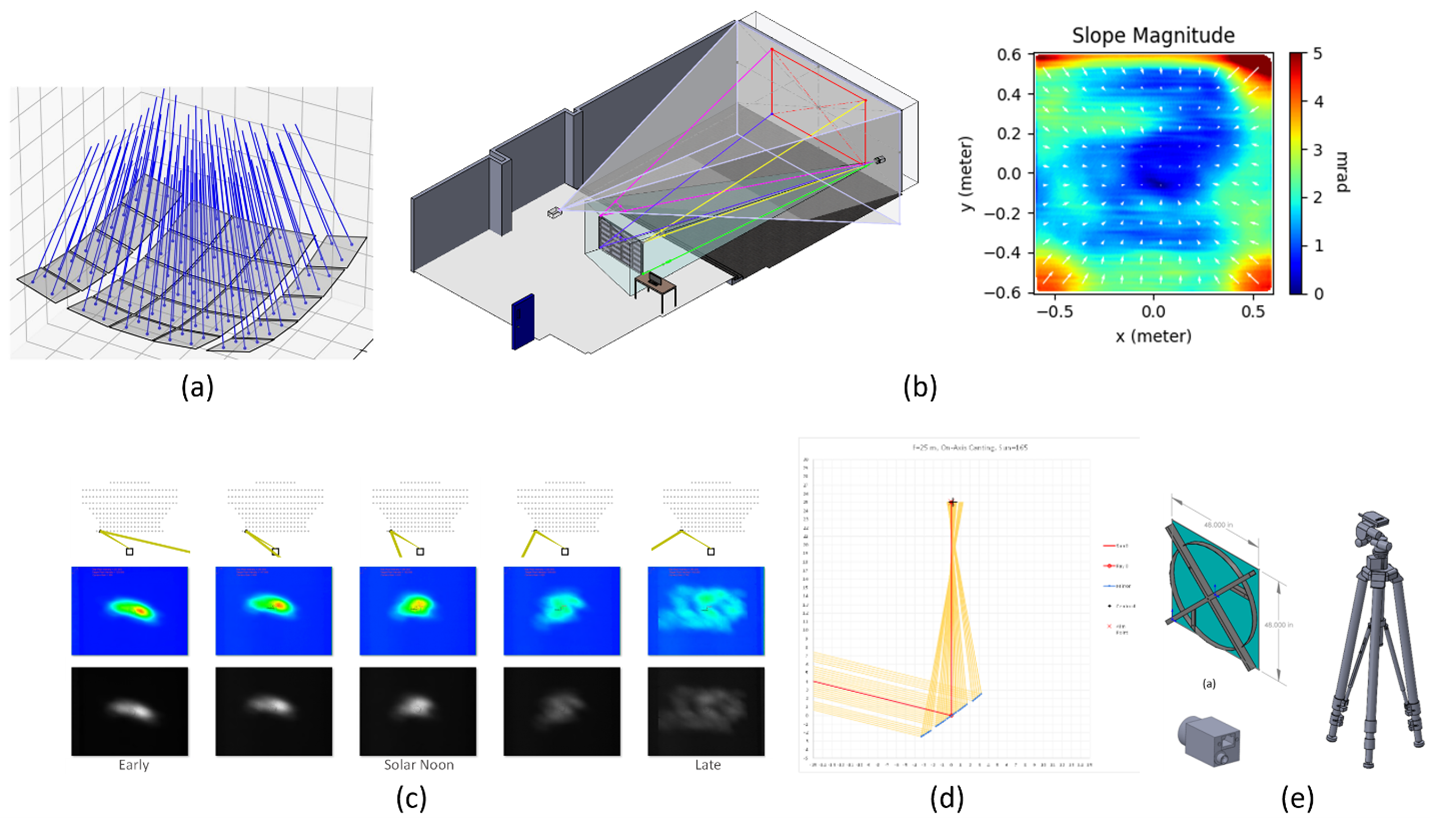

This project is developing a closed loop controls and wireless communications test bed, which will parallel a DOE SETO heliostat field refurbishment effort. This experimental test system comprising 218 heliostats will be flexible to bring in python closed-loop controls architectures to demonstrate on-sun with an approximate 200 ft. tall solar tower. This system would also enable testing of wireless controls communications such as WiFi, Mesh and radio platforms. This work is being conducted in a phased approach with a laboratory closed-loop controls test bed, prior to real-time closed loop control with 4, 16 and the subsequent 218 heliostats, where feedback is tested from one or more measurements of direct optical metrology.

Project Lead:

Ken Armijo (Sandia)

Team: Ansel Blumenthal, Haden Harper, Zachary Bernius, Luis Garcia-Maldonado

Objectives:

- Closed loop controls test bed with highly-flexible software and hardware controls, communication and optical sensors which will be communicating with both wired and wireless protocols.

- Software architectures utilized to determine optimal pointing of each heliostat, accounting for unique metrology considerations.

- Goal to decrease commissioning and O&M cost, while increasing plant performance for varying solar market flux requirements.

Approach:

- Closed-loop systems possess beam characterization system, provides feedback based on heliostat’s receiver aiming.

- Closed-loop control enables automatic calibration as part of commissioning and fine calibration on a daily or even more frequent basis.

- Hardware to enable closed-loop heliostat control capable of feedback for plant-level control.

- Provided Python software integrated within control room architecture, setup to decide which heliostats aim at receiver to maximize flux and desired pointing strategy distribution.

Status:

- Controls and real-time processing architecture being completed with validation work underway.

- Completion of Wifi communications setup with mesh communications development on-going.

The first image shows the 9 different combinations of surface and adhesive materials subjected to peel testing.

The second image shows a sample laminate stack with a 1 mm mirror supported by honeycomb before applying and edge seal structure.

Featured Project

Description:

The components and controls FY24 subtask is focused on laminating and testing coupon sandwich mirror facets with 96% reflectivity mirrors. Improving reflectivity from 93% to 96% results in significant field performance gains that offer more than a one-to-one reduction in CSP LCOE. 96% reflectivity is achieved with 1-2 mm glass mirrors as opposed to the standard 3-4 mm glass. Such thin glass is not structurally robust and therefore requires additional support. Testing with coupons provide the opportunity to learn which adhesive materials and support structures provide the most protection to the silver layer as well as robustness to hail and other damage mechanisms.

Project Lead:

Matthew Muller, NREL

Team: Matthew Muller, Stephanie Meyen, Christa Schreiber

Objectives:

- Test multiple adhesive materials including 3M adhesive tape, Ethylene Vinyl Acetate (EVA), and Polyolefin Elastomers (POE) with other stack materials including Aramid honeycomb, Pop Foam (foam from recycled plastic bottles, mirror back paint, and aluminum.

- Laminate stacks with multiple support structures and subject the samples to accelerated environmental testing and hail testing.

- Demonstrate robustness to hail and corrosion of the silver layer.

Approach:

- Conduct peel testing for bond strength between the 3 adhesives and the 4 adjoining surfaces

- Measure the performance of thin mirrors from 2 sources

- Complete accelerated damp heat, thermal cycling with humidity, UV plus humidity, and condensation testing on 10 cm samples.

- Conduct hail testing on 24-inch samples

Status:

- Peel testing is complete resulting in EVA providing the highest bond strength

- Mirror performance characterization is complete.

- 10 cm samples have been laminated with both 1- and 3-mm glass. 3 mm glass is indoor glass and was included because it does not have outdoor protective paint. This provides the opportunity to determine if adhesive layers and an edge are sufficiently hermetically sealed to protect the silver layer.

- Samples are currently undergoing damp heat, UV plus humidity and thermal cycling with humidity.

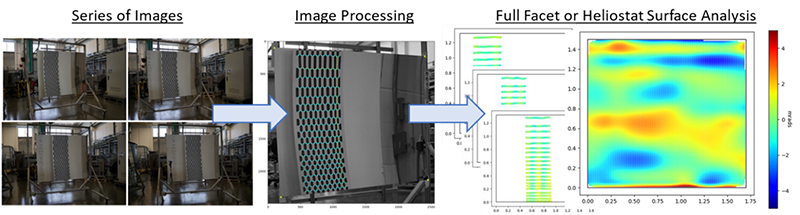

Illustration of ReTNA equipment and setup ease. Top: A ReTNA portable layout (left) and larger stationary setup (right). Several layouts have been demonstrated this year, for different applications.

ReTNA workflow for measurement with a smaller target.

Featured Project

The Reflected Target Non-intrusive Assessment (ReTNA) tool measures mirror surface slope and facet canting error for heliostat qualification, R&D, and quality assurance on the heliostat assembly line. It is designed to adopt simple, low-cost equipment such as modular, lightweight printed targets and off-the-shelf cameras.

Project Lead: Devon Kesseli (NREL)

Team: Guangdong Zhu (NREL), Kyle Kattke (Solar Dynamics)

Objectives:

- To develop and validate laboratory optical measurement technology.

- To offer the industry a lightweight, low cost, and portable system capable of fast setup and automated measurement.

- To enable accurate measurement of slope and facet canting error:

o For For heliostats of various geometries

o At varied heliostat orientations

o With varied loading applied to the heliostat

Approach:

- Using target deflection techniques to accurately measure mirror shape.

- Using photogrammetry to reduce the required precision of the setup.

- Leveraging advancements in image-processing and computer vision to automate measurement.

Status:

- Completed concept-proof stage, and repeated ReTNA testing on a commercial heliostat.

- Built initial ReTNA prototype at NREL, working on second generation system prototype.

- In next year, complete further rigorous validation campaigns with research and industry partners and collaborate with industrial partners to demonstrate commercial ReTNA layouts.

Featured Project

OpenCSP is an open-source platform including source code, applications, and data to enable collaborative development for the CSP community, supporting industry, research, and education.

- OpenCSP_Code – Both foundation classes for building new programs and ready-to-run applications, including Sandia’s SOFAST 2.0 code, all in Python.

- OpenCSP_Data – Large data sets for research, optical targets for metrology ground truth tests, and test data for OpenCSP_Code.

- OpenCSP_Mechanical – Includes an interactive CAD tool for designing deflectometry layouts, plus a gallery of CAD models to support collaborative CSP research.

- OpenCSP_Tools – Non-code tools to aid CSP analysis and understanding.

- OpenCSP_Documents – Documents supporting OpenCSP and related topics.

All are provided with an open-source license allowing unlimited use, requiring acknowledgement.

Project Lead: Randy Brost, Ph.D. (Sandia)

Objectives:

- Accelerate transfer of state-of-the-art CSP metrology and analysis tools to industry.

- Provide a resource for businesses seeking to support CSP development.

- Enable the code and data to contribute to education.

- Provide a community collaborative development environment to enable teams to build new advanced CSP applications more quickly, and to speed their deployment.

Approach:

- Establish a strong collaborative code development environment set up to support effective team code development, including automatic testing, document generation, and issue tracking.

- Provide a large corpus of difficult-to-produce CSP research data.

- OpenCSP welcomes all to use its resources and contribute to make it even better!

Status:

- As of July 2024, both code and non-code OpenCSP repositories have been operational for months, used by the OpenCSP team. We plan to announce the public opening of OpenCSP at SolarPACES in October 2024. Presentation: “OpenCSP: Collaborative Code and Data For CSP.”

- OpenCSP web portal is under construction; send inquiries to OpenCSP@sandia.gov.

Featured Project

Description: The drone-based Non-Intrusive Optical (NIO) Technology developed at NREL allows for in-situ characterization of heliostat optical errors at commercial-scale power tower CSP plants. The method will be validated using data collected from commercial solar fields, including Cerro Dominador and Crescent Dunes and compared against Beam Characterization System (BCS) measurements of tracking error at NREL’s Flatirons campus. Project Lead: Rebecca Mitchell

Project Lead: Rebecca Mitchell

Objectives:

- Update the NIO software so that it is fully automated and reliably produces optical error estimates at high volume

- Validate the reliability and accuracy of estimates of slope, tracking, and canting error produced by the NIO algorithm through repeatability testing and comparison with BCS data.

- Perform and comparison test of NIO and BCS measurements at the Flatirons campus

Approach:

- Test and refine the algorithm performance by processing drone image data collected at Crescent Dunes and Cerro Dominador.

- Install a solar collector and BCS target at NREL’s Flatirons campus.

- Perform a comparison study of NIO and BCS measurements of tracking error at the Flatirons campus.

Status:

- Made significant advancements towards commercialization of the NIO software through streamlining the data architecture and improving the reliability of the automated post-processing of data through testing of collected Cerro Dominador and Crescent Dunes data.

- A BCS has been deployed at Flatirons campus and two types of heliostats have been identified for installation at the site. 9 Heliogen heliostats have been delivered on campus and a purchased Heliuss heliostat prototype is being fabricated.

- An IF1200A hexacopter UAS has been acquired for NIO data collection and test flights were conducted at Flatirons campus.