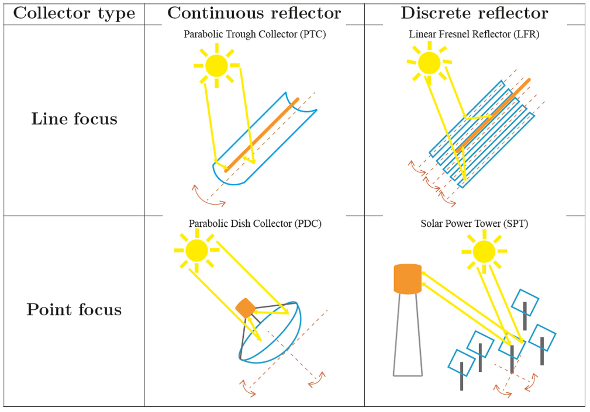

Figure 1: Types of CSP: the basic optics [a]

Background on Concentrating Solar Power

Concentrating solar power (CSP) is a renewable energy technology that uses mirrors to concentrate solar rays onto a receiver. The receiver converts that radiation to thermal energy, which can either be stored in a heat transfer fluid, used to directly generate electricity with a standard steam turbine generator, or used as process heat for industrial processes.

The four main types of CSP are parabolic trough collector, linear Fresnel reflector, parabolic dish collector, and solar power tower, as seen in Figure 1. The parabolic trough design consists of a curved mirror that reflects light onto a tube full of heat transfer fluid running the length of the trough. The linear Fresnel reflector is similar but is made up of a series of non-curved mirrors instead of a curved one. Both designs are linear, meaning they only need to move along one axis of rotation to track the sun. Parabolic dish collectors are made of a large parabolic mirror that focuses the sunlight on to a single point which has a heat transfer fluid where the energy can be stored. The power tower design consists of a large field of multifaceted mirrors (heliostats) that reflect the sunlight on to a central tower receiver that collects the radiation and stored the thermal energy. The power tower design is the most promising in terms of large-scale energy production so it will be the main topic being expanded upon here.

Figure 2: Parabolic trough plant

Figure 3: Linear Fresnel collectors at Kimberlina Solar Thermal Power Plant

Figure 4: SunCatcher 38-ft parabolic dish collectors

Figure 5: Crescent Dunes power tower plant, aerial view [b]

Figure 6: Ivanpah solar field (multi-tower)

History and Development of CSP and Heliostats

CSP development and research on heliostats began in the 1970s, upon establishment of DOE and similar initiatives internationally. This section is primarily focused on heliostats, for which the technology has progressed through three distinct phases, to date. First generation heliostats were made of laminated glass and sized about 40m2 on average. The second generation was a transitional phase in the late 1970s and early 1980s, with the primary change being an increase in size (44-57m2). The goal was to decrease cost per unit collection area by minimizing cost of components that are needed for each heliostat, regardless of size (control mechanisms, structural support, etc.). During this period, some preliminary design specifications and standards were also suggested, to place controls on performance, survival, and lifespan of components. A 30-year lifespan was suggested and has remained the standard. The third generation is the current state of the art technology, which brings even larger sizes (often over 100m2) in addition to a greater variety of research including much smaller heliostats (<1m2) and several novel designs. Optimal size, shape and design are still topics of debate, and there are many opportunities for optimization that will affect the overall cost and impact of the technology.

Current CSP plants

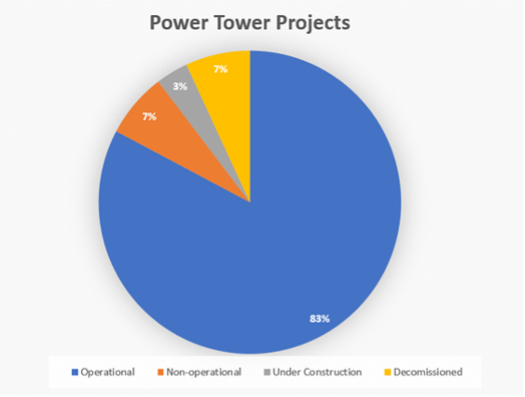

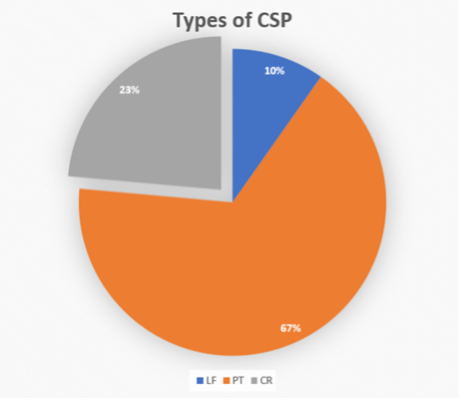

As of 2021, there are nearly a hundred active CSP plants, including 26 power tower plants, though not all of them are currently operational. A current database of CSP plants and associated information is hosted online by the international group SolarPACES , and the current numbers are summarized in Figure 7. A summary of power tower plants is shown in Appendix A, and the SolarPACES site has far more detailed information on all CSP projects, downloadable as an Excel or CSV file.

Figure 7: Current CSP Statistics, using SolarPACES data

(a) Operational status of existing power tower plants

Figure 7: Current CSP Statistics, using SolarPACES data

(b) Types of CSP plants to date: LF: Linear Fresnel PT: Parabolic Trough CR: Central Receiver

Benefits of CSP

One of the primary benefits of CSP is easy integration with thermal energy storage (TES), which allows for long term energy storage and readily dispatchable electricity. TES allows for overnight storage and on-demand conversion to electricity, adding resiliency to a highly renewable electrical grid. TES can also be used for industrial process heat, directly replacing the burning of fossil fuels. CSP electricity is currently more expensive than photovoltaic (PV), but thermal storage is cheaper than electrical storage, so there are trade-offs to both technologies. A combination of PV and CSP is generally seen as a promising route in the future of solar power.

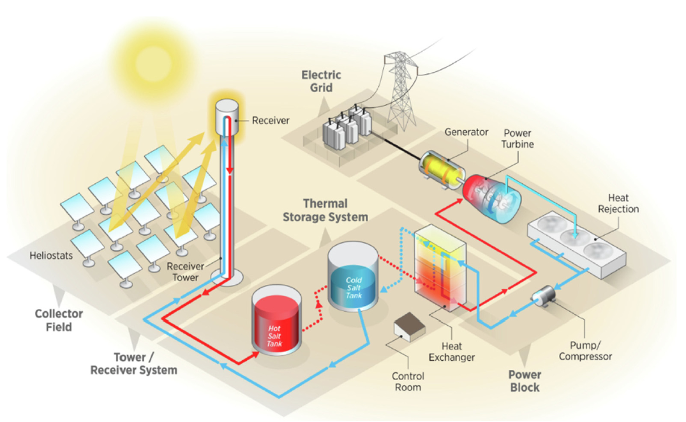

Figure 8: Schematic of a power tower plant with molten salt TES [a]

Power Tower Plant

The power tower plant is typically the largest of the CSP designs, consisting of a field of mirrors, heliostats, that track the sun throughout the day and year to maintain a constant focal point on the receiver, which consists of absorber panels of tubes near the top of the towe . These tubes are irradiated by the concentrated sunlight and absorb the incoming energy as heat, which is then transferred to the heat transfer fluid (molten salt, steam, etc.). The heat is then either stored or used to generate electricity using a traditional turbine generator, shown in Figure 8.

An Overview of Heliostats and Concentrating Solar Power Tower Plants

This downloadable report, ‘An Overview of Heliostats and Concentrating Solar Power Tower Plants,’ includes a summary of design types and concerns, components, field implementation and performance assessment of heliostats, along with the standard solar power tower plant design as a reference to those interested in heliostats and CSP tower technology.

Additional Industry Resources for Download :

- Introduction to Heliostats Document (PDF)

- List of available heliostat metrology tools (.xlsx)

- List of available heliostat software tools(.xlsx)

- List of heliostat component developers and suppliers (.xlsx)